Digital Jewelry Manufacture

Modern technologies such as 3D printers, multi-axis drilling and cutting machines, which are approved such as Milling and Lathing, have affected all industries. In the world of jewelry, this development was not a factor in decreasing manufacturing costs and increasing the quantity of production. Rather, it increased the creativity of jewelry manufacturers to focus on design instead of wasting time and effort doing traditional handicrafts.

The digital industry in jewelry has not proven its efficiency in producing modern designs that were not possible by traditional methods. Rather, it has allowed customers to give a unique experience in terms of designing exclusive jewelry for them with the ability to introduce personal touches in the design and experience it before manufacturing it for them.

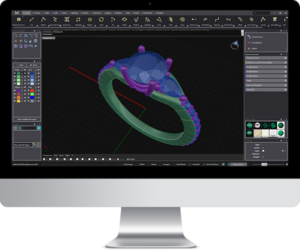

From a Sketch to 3D Digital Model

3D jewelry design programs enable designers to transfer their creativity from paper to real models in record time, as these programs provide large libraries of basic elements of jewelry from rings, bracelets, earrings and chains, in addition to different types of gemstones so that the designer can present them to the customer before Manufactured and printed using 3D printing techniques to ensure that they are suitable for the customer in terms of size and external shape.

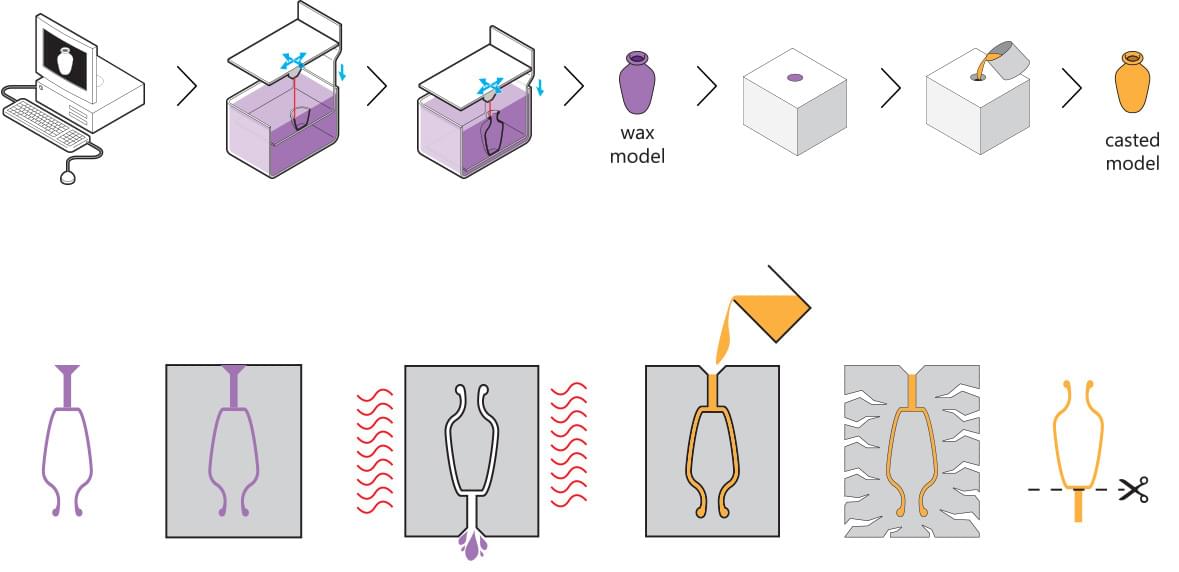

Jewelry 3D Printing

3D printing provides a suitable solution for professional jewelry manufacturers who provide their customers with unique designs that are exclusive to them, making it easier for them to make prototypes, experiment and modify them until the final model is reached. On the other hand, this technology saves the time and manpower needed to manufacture wax models for individual pieces and for small and medium quantities to be cast later.

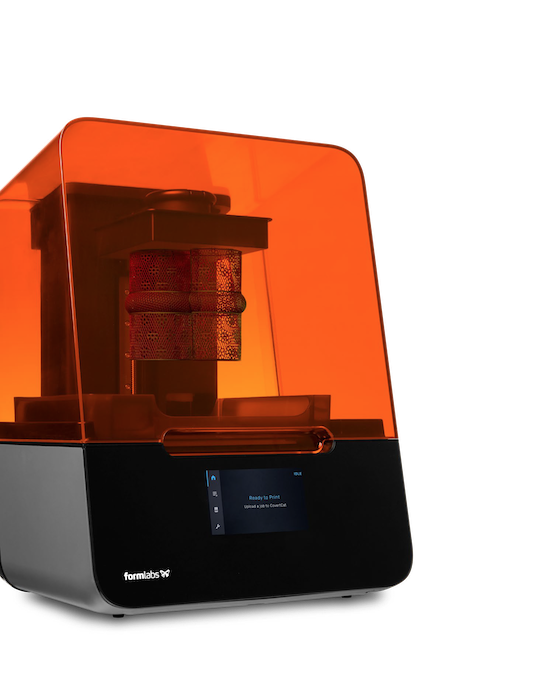

Formlabs Form 3

The Form3B uses Low Force Stereo lithography technology to give printed forms accuracy and high quality surfaces, while enabling the creation of light-touch support structures.

The Form3B printer is designed to enable dentists and laboratories to manufacture advanced dental applications with high accuracy and reliability, based on biocompatible materials in the dental fields, to make digital dental manufacturing easy and accessible to everyone.

- Printing Technology : Low Force Stereo-lithography

- Print Size: 5 x 14.5 x 18.5 CM

- Resin filling mechanism: Mechanism

- Layer thickness (XY-axis precision): 25-300 microns

- Laser resolution: 25 microns

- Laser point measurement: 85 microns

- Supports: Automatic generation mechanism easy to remove.

3D printed gold jewelry

Here are a number of different jewelry that were made using 3D printing techniques to make the wax model.